Tube OD BWG Tube ID d Tube Length L Area of one tube Cross sectional area of tube. Design Calculation of Parts Costing Dimensional Sketch of Body Flange.

Tube Layout Calculator For Shell And Tube Heat Exchangers Cheresources Com Community

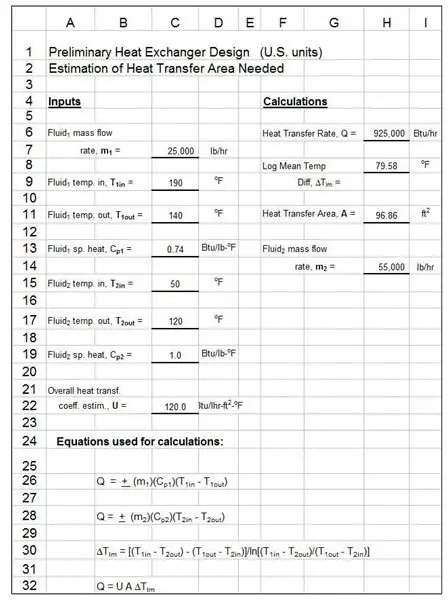

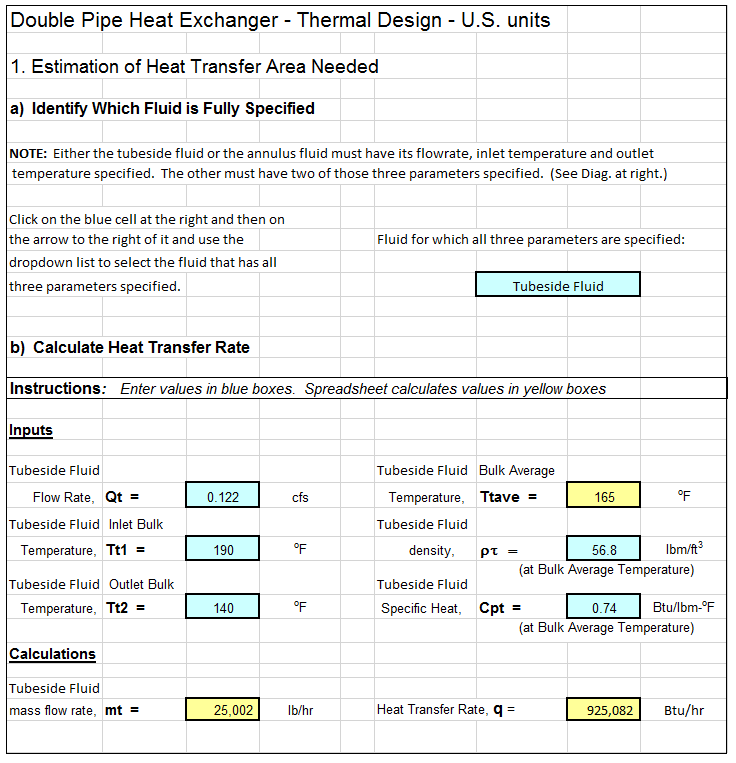

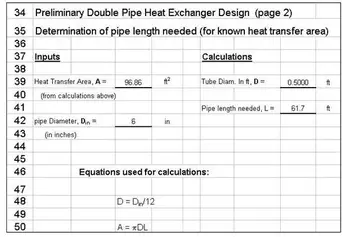

Heat exchanger calculation spreadsheet excel format.

. Input tubing OD BWG and length can be trial and error. These templates use SI. Unknown exit temperatures on both sides or Unknown two Temperatures one shell side and another tube sides.

Heat Capacity Heat Exchanged Av. It can calculate the required number of Bays Fans Tubes Tube rows and Tube bundles the Outlet Air Temperature using iteration or incrementing techniques. Shortcut Heat Exchanger Sizing.

The pressure drop calculated for shell and tube heat exchangers is that. This Excel workbook presents formulae and data for. For more information please visit the Products page.

This presentation focuses on thermal and hydraulic design of shell and tube heat exchangers Ford Bacon Davis LLC 19. Thermal Conductivity Fouling Resistance. Shell tube heat exchangers can manage fluids at high temperatures and pressures due to which they are preferred.

Learn how from the experts at SRC. Download Shell and Tube Heat Exchanger Design for Windows to compute the design calculations of shell and tube heat exchanges. Shell and tube heat exchanger design is an iterative process which goes through the following steps.

Calculate the required heat transfer area based on values needed. SHELL TUBE HEAT EXCHANGER Equipment label Shells per unit Series Parallel Surface per unit Process service Plant section Equipment name Surface per shell. This Heat Exchanger Excel Workbook provides well organized technical data in form of spreadsheet calculations tables charts and diagrams indispensible for anyone involved in the design selection operation maintenance or inspection of heat exchangers.

Shell and Tube design and rating Tube vibration analysis Air Cooler design and rating Others Plate and frame plate-fin spiral plate hairpin jacketed pipe and fired heater etc. Unknown Flow rate Unknown temperature on either shell or tube side can be calculated. Select a Tube Side product fluid and Shell Side working fluid.

Duty Area Shell and Tube velocities Number of. With shellside and tubeside inletoutlet temperatures fixed the required shellside flow is calculated corresponding to given tubeside flow. Here attached is a Spreadsheet to Design a Shell Tube Heat Exchanger with minimum number of inputs and most of the work being.

Our heat exchangers help your system work smarter. Pitch diameter of the tube diameter of the coil velocity of fluid inside the coil mass flow rate T inlet of. Units for double pipe and shell and tube heat exchanger design.

Calculation of the heat transfer profile in a component. Define process requirements for the new exchanger. Ad Designed and engineered for quality.

Design pressure at max temp Dynamic viscosity Film transfer coefficient Square Triangular 100 100 100 100 100 ft2 m2 ft2 100 ft2 m2 ft2 100 lbh kgh lbh 100 lbh kgh lbh. Choose a Model Number. Define design parameters such as - number of tube passes tube size shell ID etc.

Frictional head loss and pressure drop calculations are done with the Excel formulas in the spreadsheet template using the Darcy Weisbach equation. I am new to this website I wanted to share a few spreadsheets dont know whether this where I should share the file or not. - if you need a custom designed heat exchanger.

Air cooled condenser design calculation excel. These copper heat exchanger tubes are normally supplied in straight length in annealed half hard temper. Use your local currency such as kg.

This is a sample of the Heat Exchanger Sizing CalculatorTo access the working calculator please sign up for free membership trial. Tube and fin material. Design calculate core length from cooling load.

Helical coil heat exchanger design calculations xls. Shell and Tube Heat Exchanger Design is a comprehensive application that allows you to test and analyze the performance and rating calculations of shellheat exchangers. This is a calculator for sizing a shell and tube heat exchanger with tubeside flow fixed.

5 Tube side heat transfer. Engineering Design and GA5. Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering Column C has cells for entry of several parameter values.

Calculate the length of the tube or heat exchanger. From Thermal design calculations of Shell. Calculate the capacity rate ratio.

Design A Shell Tube Heat Exchanger On Ms Excel - posted in Process Heat Transfer. Up to 24 cash back Shell and Tube Heat Exchanger BEM Design Estimation Spreadsheet. Shell and Tube Heat Exchanger Software Features STHex Step by step design and rating calculations.

Shell side heat transfer coefficient. 5000 INR 100 USD. Heat Transferxlam Excel 200720102013 Heat Transferchm Note.

Shell Tube type segment dominated the heat exchangers market in 2018 Shell tube is the most widely used types of heat exchangers that accounted for the significant share of the heat exchangers market in 2018. Enter the fluid Flow Rate Temperature and Pressure at the heat exchanger. This is a simplified tube-shell heat exchanger design.

44 rows Shell and Tube Heat Exchanger Design software STHex. Select a suitable type of shell and tube exchanger. Download the Excel spreadsheet templates in this article to make preliminary heat exchanger design calculations.

Up to 10 cash back Description. -1 input physical properties at bottom. This web application estimates LMTD Log Mean Temperature Difference Exchanger surface area number of tubes shell diameter and number of.

- to evaluate a Model Number not shown in the calculator. They will also calculate the number of tubes needed for a shell and tube heat exchanger and to calculate the pipe length needed for a. Excel spreadsheet templates can be downloaded in US.

Heat exchanger calculations and modeling to get the output. Preface Students enrolled in Chemical Engineerings Engineering Design 2B course are required to complete a project and write a report on Design of Shell and Tube Heat Exchanger STHE The primary goal of this report is to create and establish the Graduate Attributes GAs that are required for this subject. Browse SRC industrial heat exchanger products.

Plmplm19 Grocery Price Comparison Grocery Grocery Price

Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering

Heat Exchanger Thermal Design Calculations Spreadsheetlow Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheets

Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering

Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering

Heat Exchangers Design And Calculation Excel Workbook Youtube

0 comments

Post a Comment